Exploring Automation Solutions in the Machinery Industry: A Comprehensive Guide

JM

The machinery industry is undergoing a significant transformation with the integration of automation solutions. These advancements are not only enhancing productivity but also ensuring precision and safety in operations. This comprehensive guide explores the various aspects of automation in the machinery sector, offering insights into its benefits and applications.

Understanding Automation in Machinery

Automation in the machinery industry refers to the use of technology to perform tasks that were traditionally done manually. This includes everything from robotic arms in manufacturing plants to sophisticated software that controls complex processes. The primary goal is to improve efficiency, reduce human error, and increase the speed of production.

Types of Automation Solutions

The machinery industry employs several types of automation solutions, each tailored to specific needs:

- Fixed Automation: Best suited for high-volume production, where the processes are repetitive and consistent.

- Programmable Automation: Allows for the production of different products in batches, offering flexibility in operations.

- Flexible Automation: Enables the production of various products without the need for extensive changeovers.

Benefits of Automation in the Machinery Industry

Adopting automation solutions brings numerous benefits to the machinery industry. The most prominent advantages include:

- Increased Efficiency: Automation speeds up production processes, reducing the time and labor required.

- Enhanced Precision: Machines can perform tasks with a level of accuracy that is difficult to achieve manually.

- Improved Safety: Automation minimizes human involvement in dangerous tasks, reducing the risk of accidents.

Challenges and Considerations

While automation offers many benefits, it also comes with challenges. Implementing automation solutions requires a significant initial investment, and there may be concerns about job displacement. However, it also opens up new opportunities for skilled workers in machine programming and maintenance.

Companies need to consider factors such as compatibility with existing systems, the complexity of the technology, and the potential need for employee training. Addressing these challenges thoughtfully can lead to a successful integration of automation.

Future Trends in Automation

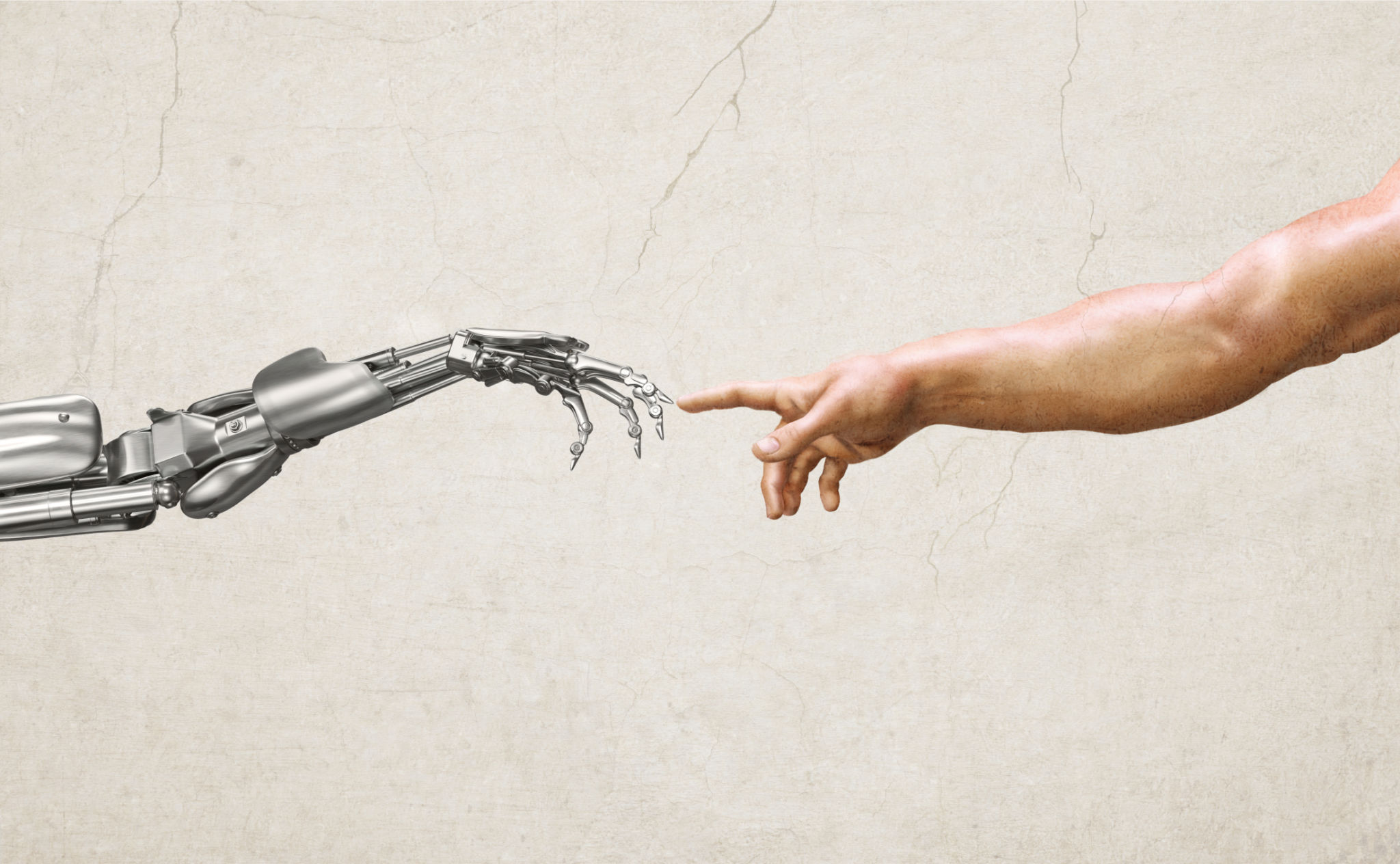

The future of automation in the machinery industry looks promising, with trends pointing towards increased connectivity and intelligence. Technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) are expected to play significant roles, enabling machines to communicate and learn from each other autonomously.

Conclusion

Exploring automation solutions in the machinery industry reveals a landscape full of potential. By understanding the types of automation, their benefits, and the challenges involved, businesses can strategically implement these technologies to enhance their operations. As the industry evolves, staying informed and adaptable will be key to leveraging the full potential of automation.