Emerging Tech Trends in Industrial Equipment Design

JM

Revolutionizing the Industry: Key Tech Trends

In today's rapidly evolving industrial landscape, technology is the driving force behind transformative changes in equipment design. As manufacturers strive for efficiency, sustainability, and innovation, new tech trends are reshaping how industrial equipment is created and utilized. Understanding these emerging trends is crucial for businesses to stay competitive and future-proof their operations.

Smart Manufacturing and IoT Integration

The integration of the Internet of Things (IoT) into industrial equipment design is perhaps one of the most significant advancements. By embedding sensors and connectivity into machinery, manufacturers can collect real-time data, enabling predictive maintenance and operational efficiency. This connectivity ensures that equipment is not only smarter but also more responsive to the needs of the industry.

Smart manufacturing allows for enhanced monitoring and control, leading to reduced downtime and optimized production processes. Additionally, it provides valuable insights into performance metrics, helping companies to make informed decisions and improve overall productivity.

AI and Machine Learning Applications

Artificial Intelligence (AI) and Machine Learning are at the forefront of innovation in industrial equipment design. These technologies enable machines to learn from data patterns and optimize their functions autonomously. From automated quality inspection to intelligent supply chain management, AI is transforming how equipment operates.

Machine Learning algorithms can predict equipment failures before they occur, allowing for proactive maintenance strategies that save time and resources. This predictive capability not only extends the lifespan of machinery but also significantly reduces unexpected downtimes.

Embracing Sustainability Through Design

As environmental concerns continue to rise, sustainable design has become a pivotal focus in industrial equipment manufacturing. Companies are now leveraging advanced materials and eco-friendly processes to minimize their carbon footprint. This includes using recyclable materials, reducing energy consumption, and optimizing resource efficiency.

- Use of energy-efficient motors and drives

- Implementation of renewable energy sources

- Designing for recyclability and reusability

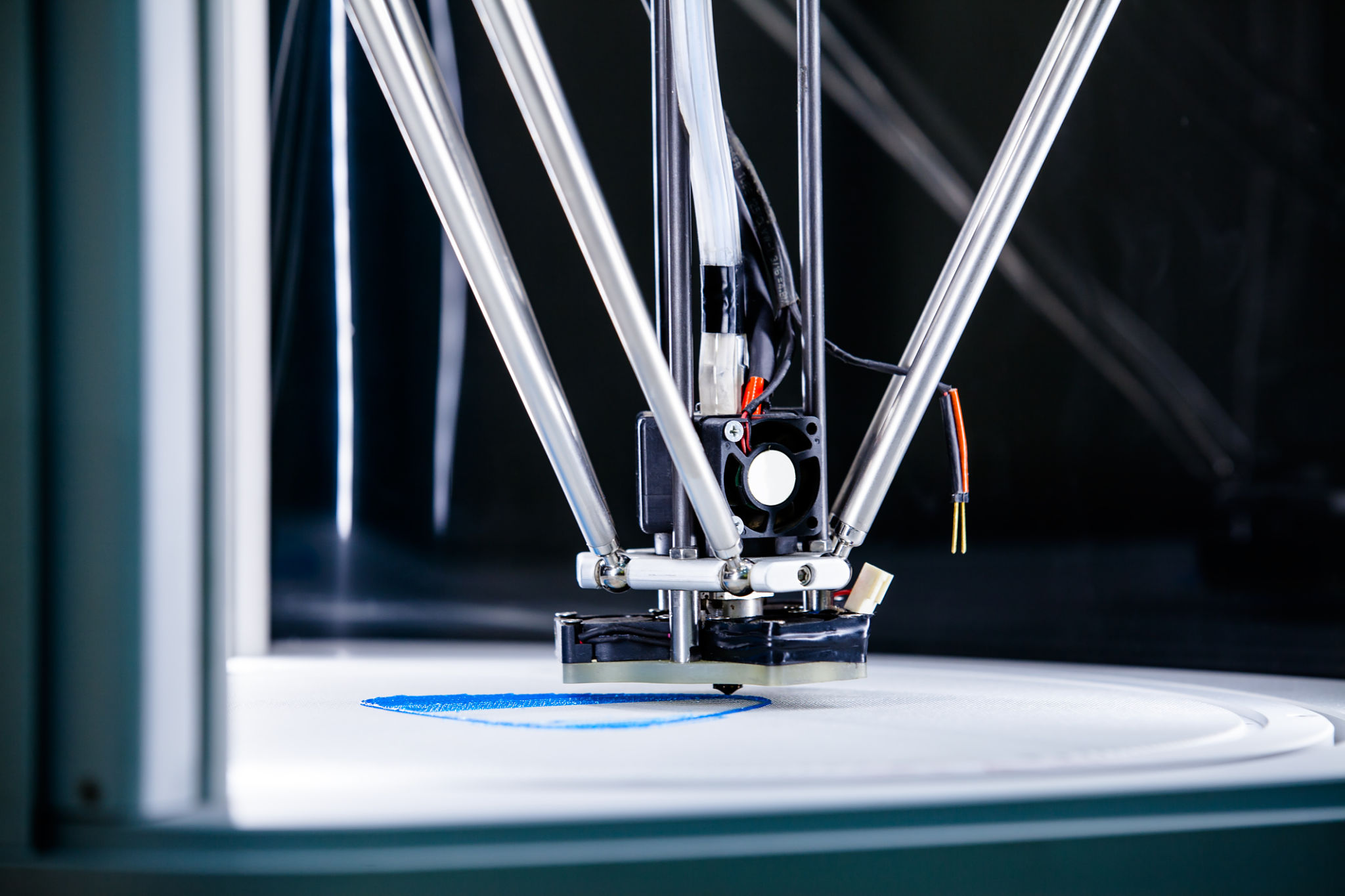

The Rise of Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is revolutionizing traditional manufacturing methods. This technology allows for the creation of complex parts with precision and minimal waste. It offers design flexibility, enabling rapid prototyping and customization of industrial components.

The impact of 3D printing on the industrial sector is profound, offering significant cost savings and reducing lead times. By enabling localized production, it also shortens supply chains, contributing to more resilient manufacturing processes.

Augmented Reality for Equipment Maintenance

Augmented Reality (AR) is gaining traction as a valuable tool for industrial equipment maintenance and training. By overlaying digital information onto the physical world, AR enhances the ability of technicians to perform complex repairs and installations with greater accuracy.

Technicians equipped with AR headsets can receive real-time instructions and visual cues, increasing efficiency and reducing the potential for errors. This technology also facilitates remote support, where experts can guide on-site personnel from anywhere in the world.

The Future of Industrial Equipment Design

The convergence of these emerging technologies is setting a new standard for industrial equipment design. As companies continue to adopt these innovations, they will unlock new levels of efficiency, sustainability, and competitiveness. Staying informed about these trends is essential for businesses aiming to lead in the ever-evolving industrial landscape.